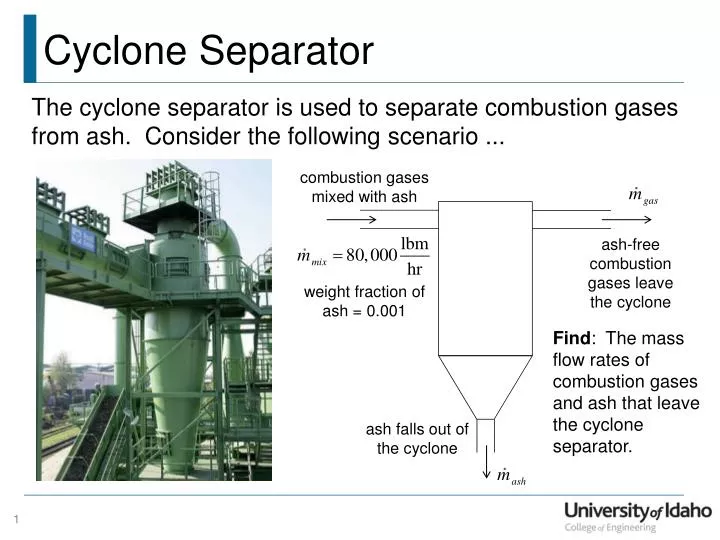

Cyclone Separator PowerPoint PPT Presentations. The present work is based on the performance of flour mill Cyclone Separator for different inlet velocity.

Cyclone Separator Ppt Video Online Download

1 - Introduction Cyclone is one of the air pollution control equipment which help to reduce the release of particulate matter into the air.

. In addition the design of cyclone separator was also based on the particle size distribution of ashdust from the wall of the chimney as presented in Table-2 column 1 and 2. Experimental results indicate that optimal cyclone design velocities which are 16 ms 3200 ftmin for 1D3D cyclones and 15 ms 3000 ftmin for 2D2D cyclones should be determined based on standard air density. Cyclones have been used for decades in industrial applications.

Basic Cyclone Design Bill Heumann. Presented here are design and calculation methods for uniflow cyclones aimed at widening the industrial usefulness of these devices Cyclone separators are in addition to fabric filters electrostatic precipitators and scrubbers the most commonly applied separators for. In a cyclone separator dirty flue gas is fed into a chamber.

The model is designed for the. STATEMENT OF THE PROBLEM. Basis For Design Of Standard Vertical KO Pot With No Internals Author.

Single-cyclone separators They create a dual vortex to separate course from fine dust. The main cylindrical part of the cyclone separator is known as the body or barrel. Sizes from sedimental water.

DESIGN OF A CYCLONE SEPARATOR. When a peak was detected a valve diverted the effluent into a specific cyclone separator. The main vortex spirals downward and carries most of the coarser dust particles.

Cyclone geometry used in this simulation stairmands optimized design Geometry aD b D D xD. Vertical cyclone separator Horizontal cyclone separator Multiple cyclone separator Single cyclone separator TYPES. Cyclone separators work much like a centrifuge but with a continuous feed of dirty air.

Design a cyclone separator for cleaning the flue gas containing fly ash with the following size distribution. Cyclone separators are considered one of the most common and widely used method of separating solid particles from fluids. Design Parameters a inlet height b inlet width Dx vortex finder diameter Ht total height of cyclone h cylinder height S Vortex finder diameter Bc cone tip diameter.

Abstract Cyclone Separator is a commonly used device to separate dust particles from gas and dust flow. Cyclone geometry in solid works. They are the principal type of gas-solid separator Most common form of particulate removal gas is spun rapidly heavier particulate matter to collect on outside of separator by centrifugal force where it is collected.

It is important to consider the air density effect on cyclone performance in the design of cyclone abatement systems. The inside of the chamber creates a spiral vortex similar to a tornado. This cyclone separator design forgoes filters and instead relies on vortex separation for the operation.

Some of the authors of this publication are also working on these related projects. It provides a cost effective solution to the problems of collecting dust. Uniflow cyclones can be effective solid-gas separation equipment when space is limited.

Fly ash from the flue gas of a power plant has to be removed before the gas is sent to an analyzer. A reverse flow cyclone separator is an industrial assembly with no moving parts and a simple design. Sizemicrons 50 Wt 15 19 24 14 8 5 15.

The focus of this paper was to design a separator that could effectively. 1013140RG222072783368 CITATIONS 0 READS 9666 1 author. Cyclone separator is a method of removing particulate from an air gas or liquid stream without the use of filters through vortex separation.

Removal of sediments of size around 48microns and larger. In the same Table-2 on column 3 and 4 particle size distribution from cyclone separator testing is presented as materials to be analyzed. Cyclone separators are ideal for separating dust with particle size greater than 5µm.

Cyclonic or particle separation is a process used to extract specifically identified particulates from a fluid stream air gas or liquid. The gradually narrowing conical section is known as the cone. Introduction Brief history What is a cyclone.

The model is designed with. These applications vary depending on the fluid from which particles are removed. There are different processes for collecting the dust in a gas stream see global overview here among them cyclones are probably one of the most widespread solution in any industryCyclone dust collectors are fairly simple from a mechanical point of view and therefore generally provide a cost effective solution.

Design and fabrication of cyclone separator Thesis August 2015 DOI. This spiral formation and the separation is shown in Figure 2. S D h D H D.

If you test an existing cyclone determine the different ratios for the actual equipment you are evaluating. The lighter components of this gas have less inertia so it. The pressure of the fluid emerging from the detector was reduced until two phases formed.

The cyclone separator and finally developed the optimized. Un-treated gas enters tangentially through the inlet at the side of the. By considering this geometric ratios the modeling of the cyclone done in solid works.

A device that separates particulate from gas fluid by centrifugal force Works simply by the kinetic energy of the incoming mixture flow stream and the geometry of the cyclone. Mechanical Engg 25 Feb 2014 Definition Cyclones are mostly used for removing industrials dust from air or process gases. In the past the primary device used to collect solute was a cyclone separator.

Dust loading in the flue of a FBC is of the order 5075 gm 3Present author found through improvised experiments that incorporation of a water scrubber after the cyclone. Design And Fabrication Of 2D2D Cyclone Separator Having Cut Point Of 68 Microns Particles With Separation Efficiency 988 View. If you design a new cyclone chose one of the standard geometry in table 1 and assume a diameter D.

Cyclone separator or water scrubber electrostatic precipitator and bag-house filter systemDry cyclone separator can remove up to 100 micron size particles. Introduction Cyclones and their design. 11132000 72548 PM.

The high efficiency of these separators is due to the unique design which enables the separator to be approximately 13 the diameter of a conventional separator. Dick Hawrelak Last modified by. 5-9-B Cyclone Separators - 5-9-B Cyclone Separators Cyclone.

Design and analysis of cyclone dust separator 1Muhammad I. Rotational effects and gravity are used to separate mixtures of solids ands fluids. 42 Calculate the cyclone dimensions.

The project presents the design and development of Cyclone Separators based on CFD along with simulations. They are widely used for collection of medium sized and coarse particles. But particles smaller than this escape.

Cyclone Separator Ppt Video Online Download

Cyclone Separator Ppt Video Online Download

Cyclone Separator Ppt Video Online Download

Ppt Cyclone Separator Powerpoint Presentation Free Download Id 2590420

0 komentar

Posting Komentar